More and more European industrial companies are bringing production they previously offshored closer to home. Central and Eastern Europe are particularly emerging as the new favourite for production locations.

Outsourcing activities to low-wage countries in Asia has been one of the

biggest trends in the past three decades. By farming out elements of

production to countries like China and Bangladesh or aspects of customer

service and software engineering to countries like India, companies reduced

costs while revenues boomed.

Leveraging outsourcing, companies have been able realise a competitive

advantage over competitors who retained work in more expensive labour

markets.

It is not a policy without some controversy, though. Offshoring to take

advantage of low-wages often saw companies take advantage of labour in

countries which suppressed organised labour, and where human rights

legislation was rarely applied – if it existed at all.

Decades of criticism from ethical consumers has come to a head in recent

years – with more than one-third of customers in the UK alone now willing

to spend more to ensure their products are environmentally and socially

responsible.

At the same time, the coronavirus crisis has exposed the brittle

aspects of many international business ecosystems. With many companies

having endured a tough 2021, and seen their pandemic recovery slowed by

scarcity of resources due to issues in their supply chain, as ethical criticism

continues to mount, executives have started to look differently at the design

of their supply chains.

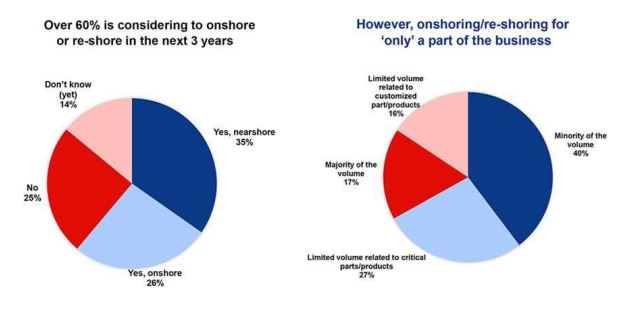

The Global Reshoring & Footprint Strategy report shows that more than 60% of supply chain executives expect to return some of their Asian production to Europe and the US.

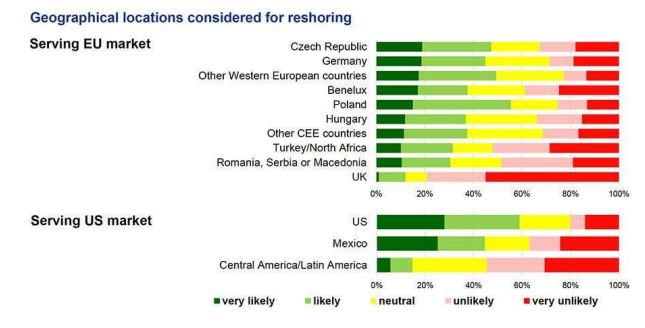

Companies from Europe are mainly looking at Central and Eastern Europe as

possible production destinations. These nearshore destinations currently

have higher labour costs, but in the shadow of the pandemic, Haex believes

manoeuvrability and flexibility have become more important than low

labour costs.

Easier said than done

A survey was conducted among industrial companies. These include parties

in mechanical engineering, the automotive industry, consumer products

and pharmaceutical production. However, it is important for these

companies not to get ahead of themselves.

On top of geo-political tensions causing problems across Eastern Europe,

dismantling all production in any country is not an easy thing to do.

Companies often have to deal with long-term contracts for housing,

production assets, the supply of materials and personnel, among other things

– which will make a swift exit impossible. In addition, there are several

barriers that need to be overcome if they are to re-integrate themselves into

the business ecosystem of Europe.

“High operational costs in Europe and the US due to limited scale and the

absence of large and broad supplier networks are the main barriers. We see this

every day in our consultancy practice. A decision to reshoring is really drastic for

a company and requires careful consideration.”