As Industry 4.0 takes hold, industrial automation and robotics are replacing many manual tasks in manufacturing. However, when it comes to visual quality inspection, most production lines still employ human workers in the tedious task of examining products and judging defects.

The biggest drawback of manual visual inspection is that humans make mistakes. Tired workers often miss defects that ‘escape’ the quality screens on the production floor and leak into finished goods packages or into integrated systems. When these defects are discovered or surface at a later stage often by end customers, users or consumers, it is too late and very costly to fix.

The Cost of Poor Quality (CoPQ) in these cases is significant. It includes – among other elements – the costs of returned or rejected goods (RMA), scrap, rework and in many cases the negative impact on brand reputation and end customer dissatisfaction.

Israel based Kitov is paving the way towards smart manufacturing, by developing the technology to enable smart computer-driven visual inspection and support manufacturers along their digital transformation path.

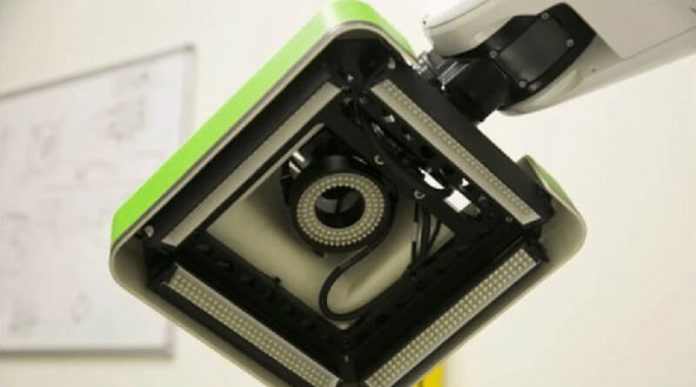

KITOV ONE is a Smart 3D, Universal System that can effectively inspect virtually any product. Leveraging advanced 3D computer vision and deep-learning algorithms, KITOV ONE achieves unprecedented levels of detection, eliminating the tedious work and inconsistent results associated with manual inspection. KITOV supports complex 3D structures, numerous materials, and complete inspection specifications.

By imitating human learning processes, KITOV ONE features an intuitive method to teach the system how to optimally inspect almost any product. Setting up the system does not require programming skills or knowledge of robotics or optics. KITOV ONE software computes and controls the processes of image acquisition and image processing by using pre-set algorithms called detectors. Artificial intelligence capabilities are used to find and classify defects.

“We have developed artificial intelligence (AI) systems for advanced manufacturing that can be intuitively trained within a few hours by a non-expert to automatically plan and perform sophisticated visual inspection tasks on complex 3D products at the highest performance levels.” states Dr. Yossi Rubner, CTO and Founder of Kitov.ai.

By using dashboards and Big Data Analytics Kitov helps manufacturers to identify trends and proactively attend to quality issues early on and by providing powerful insights about manufacturing process and product design can support root cause analysis and elimination of defects.