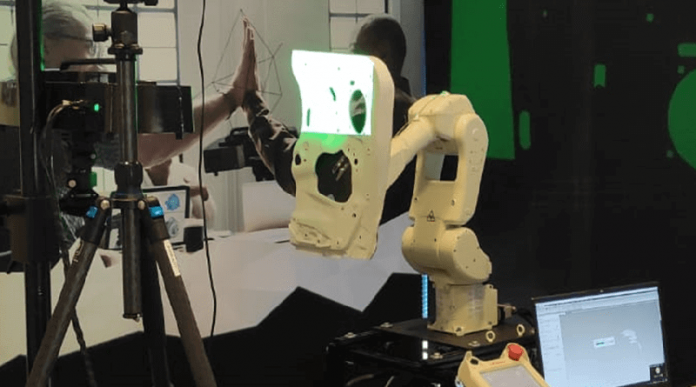

SMARTTECH3D has released Robotized, a combined industrial robot and 3D scanner solution, offering real-time production line automated quality control.

Robotized is a fully automated measurement solution providing contactless digitalization of small and medium sized parts and assemblies. The system uses the latest SMARTTECH3D optical 3D scanning technology which incorporates advanced robot capabilities to completely automate the 3D measuring process.

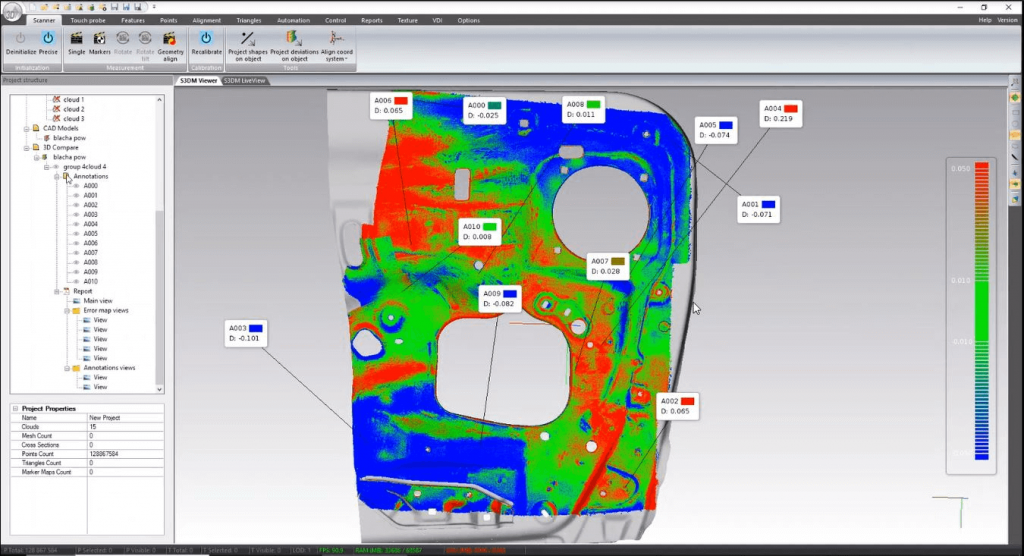

SMARTTECH3D Robotized enables effortless alignment and measurements of parts with even the most diverse sizes and shapes. Moreover, the newest version of SMARTTECH3D measure software enables the projection of the generated deviation color map directly back onto the surface of the measured part, which allows rapid identity and determination of part areas needed to be corrected. Additionally, the software facilitates generation of customized quality control reports.

Uniquely the integrated robotic measuring solution utilizes the robot to manipulate the part within the scanning sensor field of view and relies upon the generated spatial coordinates of the robot for position data.

SMARTTECH3D Robotized offers automatic system calibration along with the possibility of scanning sensor change allowing for the scanning of objects with complex shapes requiring different precision levels and point measurement density. The easy to use software enables control of both the robot and measurement plan management without the necessity for specialized knowledge.

SMARTTECH3D Robotized minimalizes human involvement in the measuring process and offers:

– Precise analysis of generated 3D data

– Automatized deviation analysis

– Comparison of 3D scanning results with CAD model (deviation color map)

– Projection of deviation color map directly back onto the part

– Scanning sensor changes to adjust the field of view