Programming of complex operations on Swiss-types and turn-mills includes simulation with automated remaining stock updates.

Esprit CAM, part of Hexagon, is said to offer flexibility in Swiss-type and turn-mill machining, enabling simple programming of complex parts. It accomplishes this with features including a robust system interface that handles a variety of operations including re-chucking, broaching, thread whirling and pinch turning/milling, the company says.

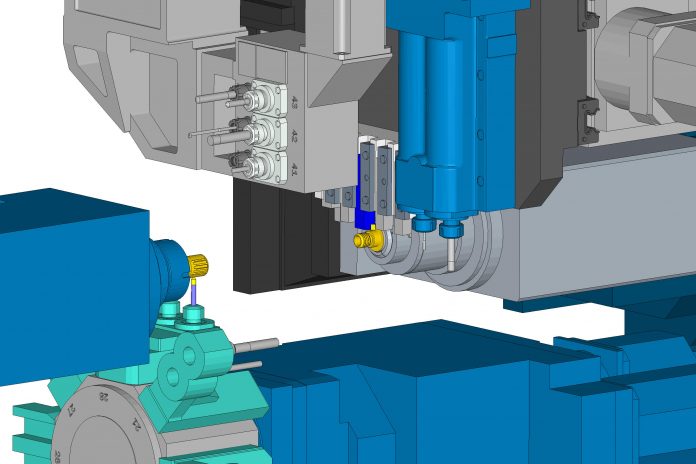

Esprit’s Millturn solution, SolidMillTurn, can program and test complex operations such as axis synchronization, superimposition, and composite operations without fear of collisions. Users can also expect to quickly output NC code with stable and accurate factory-certified postprocessors.

Esprit’s Swiss-style solution enables accurate simulation with stock automation which constantly updates the stock during the simulation, taking new clearances as the part takes shape. True simulated cycle times also enable users to provide accurate job quotes to help maintain company profits and customer satisfaction.